Inside the Clean Factory: Revolutionizing Watchmaking Efficiency

In the heart of the Swiss Alps, where the art of horology has flourished for centuries, a quiet revolution is taking place. Welcome to the clean factory—an innovative paradigm that is reshaping the landscape of watchmaking efficiency. Gone are the days when craftsmanship meant solely manual labor and intricate tools; today,state-of-the-art technology harmonizes with traditional artistry to create an habitat that promotes both precision and productivity. This article delves into the inner workings of these modern factories, exploring how advanced automation, meticulous cleanliness, and sustainable practices are transforming the industry. As we turn back the gears of time, we invite you to discover how the clean factory is not merely a space for assembly, but a beacon of progress in an age-old craft.

Table of Contents

- Exploring Innovative Technologies in Clean Factory Design

- Streamlining Production Processes for Maximum Precision

- Ensuring Sustainability: Eco-Friendly Practices in Watchmaking

- Empowering Workforce Efficiency through Smart Automation

- Q&A

- Insights and Conclusions

Exploring Innovative Technologies in Clean Factory Design

In the quest for unparalleled precision in watchmaking, manufacturers are increasingly turning to cutting-edge technologies that redefine the concept of a clean factory. Among these innovations, robotic automation plays a pivotal role, ensuring that intricate components are assembled with the utmost accuracy while minimizing human error. This technological leap not only enhances productivity but also maintains a sterile environment, free from contaminants that could compromise the delicate workings of timepieces. The integration of machine learning algorithms enables these factories to analyze production processes in real-time, optimizing workflows to further enhance efficiency levels.

Moreover, sustainable practices are becoming a hallmark of modern clean factory designs.Renewable energy sources, such as solar panels and wind turbines, are increasingly being integrated into the infrastructure, providing a green alternative to traditional energy needs. This approach not only reduces the carbon footprint but also fosters a sense of corporate responsibility.Additionally, advanced air filtration systems are employed to ensure that the workspace remains uncontaminated, creating an optimal setting for meticulous craftsmanship. The combination of these elements fosters an ecosystem where innovation flourishes, allowing for the creation of exquisite watch models while safeguarding the planet’s resources.

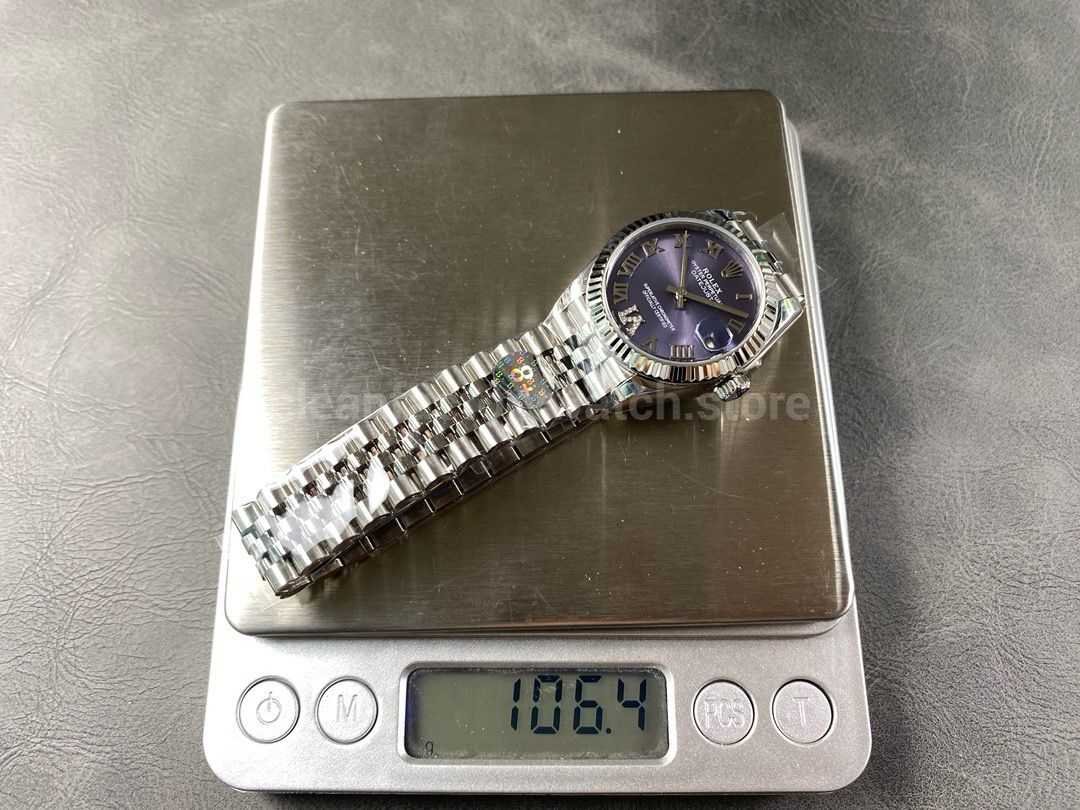

Streamlining Production Processes for Maximum Precision

In the quest for unparalleled quality, each stage of the production line has been meticulously analyzed and redefined. By integrating cutting-edge technologies,the clean factory model emphasizes automation and smart manufacturing techniques that enhance precision. Machines equipped with advanced sensors detect even the minutest discrepancies, allowing for immediate adjustments that minimize waste and maximize performance. This seamless integration ensures that every component is crafted to perfection, significantly increasing the overall output consistency.

Moreover, fostering a culture of continuous advancement plays a critical role in achieving excellence.Regular training sessions are conducted to equip the workforce with the latest skills in precision craftsmanship. The implementation of lean manufacturing principles streamlines workflow and reduces bottlenecks, ultimately fostering an environment where feedback is actively sought and valued. This commitment to excellence not only enhances precision but also builds resilience against the certain challenges of production:

- Elimination of non-value added activities

- Reduction of inventory costs

- Enhanced collaboration across departments

| Process Step | Description | Benefits |

|---|---|---|

| Material Sourcing | Using high-quality, sustainable materials | increases durability and reduces waste |

| Machining | Utilizing precision CNC machines | Ensures exact measurements and cuts |

| Quality Control | Implementing real-time monitoring systems | Immediate detection of defects |

Ensuring Sustainability: Eco-Friendly Practices in Watchmaking

In the world of horology, the industry is witnessing a transformative shift towards more sustainable practices that echo the ideals of eco-conscious consumers. Adopting green technologies, many watch manufacturers are exploring solutions that significantly reduce their carbon footprint. By integrating renewable energy sources such as solar or wind power into their production lines, they not only enhance efficiency but also align their operations with global sustainability goals. Using recycled materials has become a hallmark of modern watchmaking, where brands are increasingly sourcing recycled metals and responsible leather alternatives, ensuring that each piece reflects a commitment to preserving the planet.

Moreover, many watchmakers are turning to innovative methods in their factories that emphasize waste reduction and resource conservation. Closed-loop systems are implemented to minimize water consumption and recycle waste, making the production process not only cleaner but also more efficient. Additionally, the use of biodegradable materials in packaging is becoming increasingly prevalent, allowing consumers to enjoy luxury without the environmental toll. The industry has also embraced digital solutions, utilizing smart technology to track and manage resources meticulously, ensuring every component of the manufacturing process is optimized for sustainability.

Empowering Workforce Efficiency through Smart Automation

In the cutting-edge realm of watchmaking, integrating smart automation is becoming a game changer for enhancing productivity and precision. By adopting advanced robotic systems for assembly, manufacturers can significantly reduce cycle times while maintaining impeccable craftsmanship. This technological synergy facilitates a seamless flow within production lines,allowing skilled artisans to focus on intricate details rather than repetitive tasks. The result is a shift in workforce dynamics where employees are empowered to contribute creatively, adding value in ways that machines cannot replicate.

The implementation of automation extends beyond just robotics; it encompasses data analytics and real-time monitoring systems that optimize every facet of operations. By harnessing this technology, companies are able to:

- Analyze workflow efficiency without interrupting production.

- Predict equipment maintenance needs, reducing downtime.

- Enhance quality control processes through consistent monitoring.

As the industry evolves, those who invest in smart automation will not only elevate their operational capabilities but will also create an empowered workforce—one that is equipped with the tools and freedom to innovate in the meticulous art of watchmaking.

Q&A

Q&A: Inside the Clean Factory: Revolutionizing Watchmaking Efficiency

Q: What does the term “Clean Factory” refer to in the context of watchmaking?

A: The term “Clean Factory” refers to a modern, streamlined manufacturing environment designed to minimize contamination and maximize efficiency. In the context of watchmaking, it embodies advanced techniques and technologies aimed at creating precision timepieces in a controlled atmosphere, ensuring that every component remains free from dust and impurities.Q: How does the Clean Factory concept improve the efficiency of watch production?

A: The Clean Factory concept enhances efficiency by integrating automation and lean manufacturing principles. With optimized workflows, reduced human errors, and real-time monitoring of production processes, factories can significantly decrease lead times while increasing the accuracy of their timepieces. The use of specialized air filtration systems and controlled lighting also ensures that the delicate components are well-protected throughout the manufacturing process.

Q: What role does technology play in the Clean Factory approach?

A: Technology is at the heart of the Clean Factory approach. State-of-the-art machinery and robotics are employed to perform intricate tasks that require precision, while advanced software systems manage inventory, quality control, and production planning. This synergy between technology and craftsmanship allows for a seamless production flow, where each step is meticulously monitored and adjusted as necessary.

Q: Can you discuss the environmental impact of Clean Factories in watchmaking?

A: Clean factories prioritize sustainability by utilizing energy-efficient processes and materials. Many incorporate renewable energy sources, such as solar power, to reduce their carbon footprint. Additionally, waste management systems are designed to recycle materials and minimize environmental impact, demonstrating that efficiency and responsibility can go hand in hand in modern watchmaking.

Q: How do artisans adapt to the Clean Factory model?

A: Artisans adapt to the Clean Factory model by embracing new tools and techniques while maintaining their traditional skills. Training programs are implemented to ease the transition, allowing craftsmen to work alongside advanced machinery.This combination of artisanal techniques and modern technology not only enhances productivity but also preserves the artistry that has defined watchmaking for centuries.

Q: What challenges arise with the implementation of Clean factories, and how are they addressed?

A: One of the main challenges is the initial investment in technology and training, which can be significant. To address this, many companies conduct thorough cost-benefit analyses to demonstrate long-term gains from efficiency and reduced error rates. Furthermore, ongoing support and progress programs are vital to ensure employees are continuously skilled in both technical and craftsmanship areas, fostering a culture of innovation and adaptability.

Q: What can we expect in the future of watchmaking with the continued evolution of Clean Factories?

A: The future of watchmaking with the Clean Factory model looks promising. We can expect even greater precision, more sustainable practices, and increasing customization options for consumers. advances in artificial intelligence and machine learning may further enhance production processes, allowing for quicker adaption to market trends and customer preferences. Ultimately, the Clean Factory may redefine not just efficiency, but also the way we perceive and appreciate fine watchmaking.

Insights and Conclusions

As we bid farewell to the inner workings of the clean factory, it’s evident that the evolution of watchmaking is not merely a tale of precision instruments and intricate designs, but a profound transformation in how we conceive efficiency and sustainability in craftsmanship. The marriage of advanced technology and traditional techniques has forged a path toward a new era where every tick of the watch embodies not just time, but a commitment to innovation and environmental stewardship.

In embracing this revolution, the clean factory stands as a beacon of possibility, proving that time-honored traditions can thrive amidst disruptive change. As watchmakers continue to refine their processes within these pristine confines, we are reminded that the future of watchmaking is not just about making timepieces; it’s about crafting meaningful legacies that resonate for generations to come. As we look ahead, one thing is clear: in the heart of the clean factory, time is not just measured; it is indeed transformed.