Inside the Clean Factory: Revolutionizing Watch Production

Inside the Clean Factory: Revolutionizing Watch Production

In an era where precision meets innovation, the realm of watch manufacturing is undergoing a transformative shift. As the world becomes increasingly attuned to sustainability and technological advancement, the facade of conventional craftsmanship is giving way to a new breed of production—the clean factory. imagine a space where every tick of the clock is not only a testament to meticulous artistry but also a reflection of eco-conscious practices and advanced methodologies. In this exploration, we delve into the heart of this revolutionary approach, unveiling the seamless integration of cutting-edge technology, sustainable materials, and rigorous quality control that are redefining what it means to create a timepiece in the modern age. Join us as we navigate the intricate workings of the clean factory, where innovation and integrity harmoniously converge to shape the future of watchmaking.

Table of Contents

- Understanding the Clean Factory Concept in Watch Production

- Implementing Sustainable Practices for enhanced Efficiency

- Integrating Automation and Technology in Manufacturing Processes

- Cultivating a Culture of Quality Control and Continuous Improvement

- Q&A

- The Conclusion

Understanding the Clean Factory Concept in Watch Production

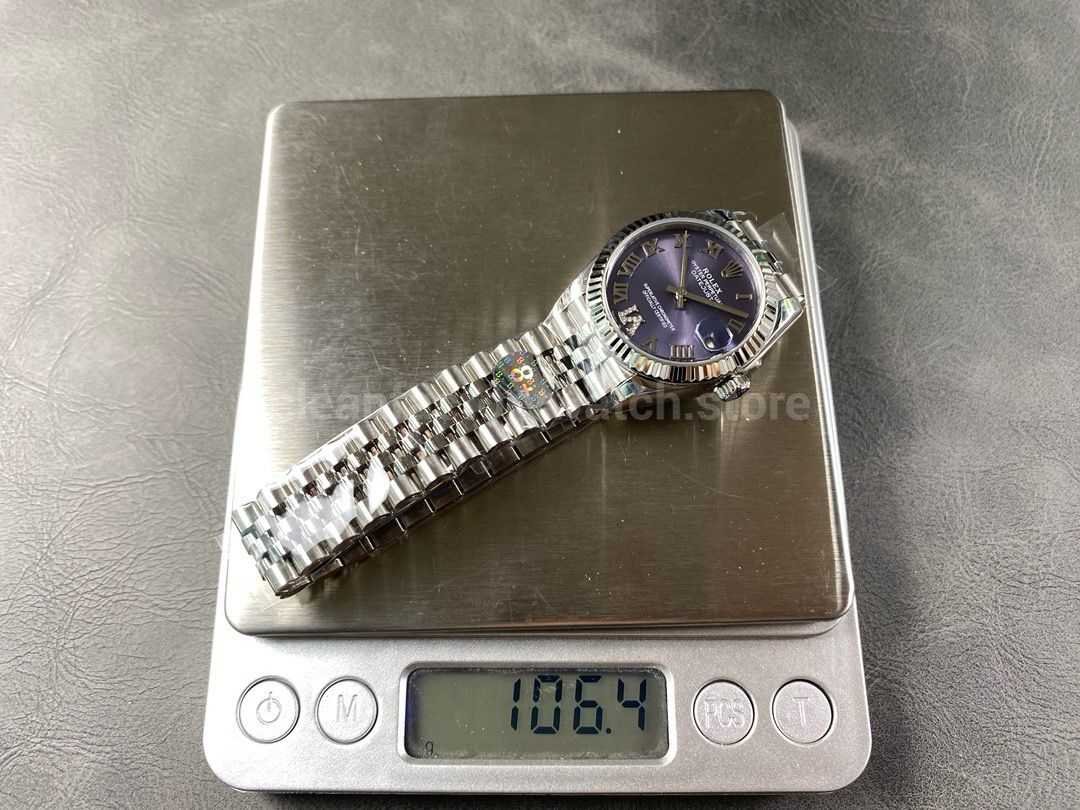

The Clean Factory concept in watch production emphasizes a contamination-free environment that ensures utmost precision and quality in every watch produced. A meaningful aspect of this concept is the rigid air quality control systems that filter out even the smallest particles from the workspace, safeguarding the delicate components during assembly. The result is a manufacturing process that fosters reliability, reduces maintenance downtime, and enhances the lifespan of each timepiece. By employing advanced technology such as HEPA filters and positive pressure systems, manufacturers can maintain ideal conditions that mirror the excellence of Swiss craftsmanship, producing watches that stand the test of time.

Another vital element of the Clean Factory approach is the request of lean manufacturing principles. This methodology aims to eliminate waste and optimize productivity by focusing on streamlined workflows and minimizing unnecessary movement. Key principles include:

- Standardization of Processes: Uniform procedures for every task minimize variability.

- Just-In-time Production: Components are delivered as needed,reducing excess inventory.

- continuous Improvement: Feedback loops encourage ongoing refinement of the production process.

Tables and visual aids are also commonly used within a clean factory environment to enhance communication and traceability.Below is a simple example of a table that illustrates the essential components of a Clean Factory:

| Component | Function |

|---|---|

| HEPA filters | Capture airborne particles to maintain air quality. |

| Positive Pressure Systems | Prevent contamination by ensuring clean air flow. |

| Automation Tools | Enhance precision and reduce human error. |

Implementing Sustainable Practices for Enhanced Efficiency

In the quest for operational excellence, the integration of environmentally amiable practices has become synonymous with increased efficiency. By re-evaluating supply chain processes, manufacturers can considerably reduce waste while optimizing resource utilization. Some key methods include:

- Utilizing Renewable Energy: Transitioning to solar or wind energy reduces reliance on fossil fuels.

- Implementing Circular Manufacturing: Emphasizing recycling and repurposing materials limits waste and extends product lifecycle.

- Adopting Lean Manufacturing Principles: Streamlining operations minimizes excess and maxes out efficiency.

Furthermore, workforce engagement in sustainability initiatives creates a culture of innovation and accountability. Training employees to identify and implement green practices not only fosters a sense of ownership but also directly impacts productivity. Triumphant companies often track their sustainability progress using key performance indicators (KPIs).Below is an example of potential metrics used to measure effectiveness:

| KPI | Description | Target |

|---|---|---|

| Energy Consumption | Overall energy used per unit produced | Reduce by 20% annually |

| Waste Reduction | Percentage of waste recycled or reused | Achieve 75% recycling rate |

| Employee Training | Number of hours spent on sustainability training | 10 hours per employee annually |

Integrating Automation and Technology in Manufacturing Processes

As the world of watch production evolves, manufacturers are increasingly looking toward automation and advanced technologies to streamline their operations and enhance product quality. by integrating robotics, artificial intelligence, and machine learning, production lines can achieve unprecedented levels of efficiency. Robotic arms can handle complex assembly tasks with precision, while AI algorithms monitor quality control in real-time, significantly reducing human error. With the use of internet of Things (IoT) devices, manufacturers can gather data continuously, enabling predictive maintenance and minimizing downtime.

This innovative approach not only enhances productivity but also promotes sustainability within the manufacturing environment. Implementing smart technologies allows for better resource management and energy efficiency. The incorporation of automated guided vehicles (AGVs) in material handling minimizes waste and optimizes space utilization. Moreover, with the ability to quickly adapt to changing market demands, manufacturers can produce customized watch models at scale. The future of watch production is undeniably tied to the seamless integration of cutting-edge technology in every facet of the manufacturing process.

Cultivating a Culture of Quality Control and Continuous Improvement

in the heart of our clean factory, we believe that excellence is not just a goal but a journey. By fostering an environment where quality control and continuous improvement are embedded into every process, we empower our team to take ownership of their work and strive for the highest standards. This commitment manifests in rigorous training programs and open communication channels, where feedback is exchanged freely and implemented rapidly.Key strategies include:

- Regular Training Sessions: Keeping the team updated on best practices.

- Real-time Quality Audits: Ensuring immediate corrective actions when issues arise.

- Employee Empowerment: encouraging team members to suggest improvements.

By making quality a shared responsibility, we cultivate a culture that values every individual’s contribution. We also implement a systematic approach to monitor performance, using metrics that highlight areas for improvement.The following table outlines the key performance indicators that we track diligently to measure our success in fostering this culture:

| Indicator | Description | Target Value |

|---|---|---|

| Defect Rate | Percentage of defects found during quality checks | Less than 2% |

| On-Time Delivery | Percentage of projects delivered by the deadline | Over 95% |

| Employee Suggestions Implemented | Number of employee suggestions adopted each quarter | 10+ suggestions |

Q&A

Q&A: Inside the Clean Factory – Revolutionizing Watch Production

Q1: What is a “clean factory,” and why is it importent for watch production?

A1: A clean factory is a controlled environment that minimizes pollutants, dust, and other contaminants to ensure the highest quality in manufacturing processes. In watch production, a clean factory is crucial as even the tiniest speck of dust can affect the delicate components of a timepiece. This environment not only increases the precision of assembly but also enhances the longevity and reliability of the watches produced.

Q2: How does the clean factory concept differ from traditional watch manufacturing facilities?

A2: Traditional watch manufacturing facilities frequently enough prioritize functionality over cleanliness, which can lead to exposure to various contaminants. In contrast, clean factories implement stringent protocols, such as air filtration systems, humidity control, and strict personal hygiene measures for workers. This level of meticulousness represents a shift towards a more modern, quality-centric approach to watch production, ensuring that every component remains pristine until the final assembly.

Q3: What technological advancements drive the revolution in watch production at clean factories?

A3: The revolution in watch production is fueled by advancements in automation, artificial intelligence, and robotics. Automated assembly lines equipped with AI allow for precise and rapid production, reducing human error. Additionally, advanced quality control systems monitor every stage of production in real-time, ensuring that any potential defects are identified and corrected immediately, enhancing overall product integrity.

Q4: How does the focus on cleanliness and technology affect the workforce in watch production?

A4: The integration of clean factory practices and technology transforms the role of the workforce. workers are now trained not only in traditional craftsmanship but also in operating sophisticated machinery.This shift encourages a culture of continuous learning and adaptation, positioning workers as skilled technicians rather than mere assemblers. Moreover, the focus on cleanliness fosters a healthier work environment, boosting morale and productivity.

Q5: What impact does the clean factory initiative have on sustainability and environmental practices in watchmaking?

A5: The clean factory initiative aligns with sustainability efforts by minimizing waste and optimizing resource use. By implementing efficient manufacturing processes and sustainable materials, clean factories reduce their ecological footprint. Furthermore, advanced recycling systems ensure that production waste is managed responsibly, contributing to a more sustainable watchmaking industry.

Q6: Are there any challenges associated with transitioning to a clean factory model for watch producers?

A6: Absolutely. Transitioning to a clean factory model involves significant upfront costs for infrastructure, technology, and training. Additionally, existing workers must adapt to new processes and practices, which can lead to initial resistance. However, these challenges are often outweighed by the long-term benefits of improved product quality, efficiency, and customer satisfaction, as brands increasingly recognize the value of a clean production environment.

Q7: What does the future hold for watch production in clean factories?

A7: The future of watch production in clean factories looks promising. As consumer demand for high-quality, precise timepieces continues to rise, the clean factory model will likely become the standard in the industry. Innovations in technology and sustainability will further refine production processes, ensuring that future generations of watches not only embody remarkable artistry but also reflect a commitment to responsible manufacturing practices. The clean factory is not just a trend; it’s a pivotal chapter in the evolution of horology.

Q8: How can consumers recognize watches produced in clean factories?

A8: Consumers may look for certifications or brand statements that highlight their commitment to clean manufacturing practices. Labels or marketing materials may note standards met for cleanliness and technology used in production. Additionally, brands that embrace clarity in their supply chain often share insights into their production methods, allowing consumers to make informed purchasing decisions that align with their values regarding quality and sustainability.

The Conclusion

As we close the door on our exploration of the clean factory and its transformative impact on watch production, it becomes clear that we stand at the precipice of a new era in manufacturing. The meticulous attention to detail, the embrace of technological advancements, and the unwavering commitment to environmental stewardship chart a promising course for the future of horology. With every tick, these innovations not only enhance the precision and durability of timepieces but also honor the enduring legacy of craftsmanship that has defined the industry for centuries.

As consumers, we are called to embrace this evolution — to wear not just a watch, but a testament to the harmony of tradition and cutting-edge innovation. The clean factory is more than a production space; it is a beacon of possibility where the artistry of watchmaking meets sustainability and efficiency. In the world of horology, time will surely tell how these changes shape our relationship with time itself. We invite you to keep watching, for the future looks as radiant as the polished surfaces of these exceptional creations.